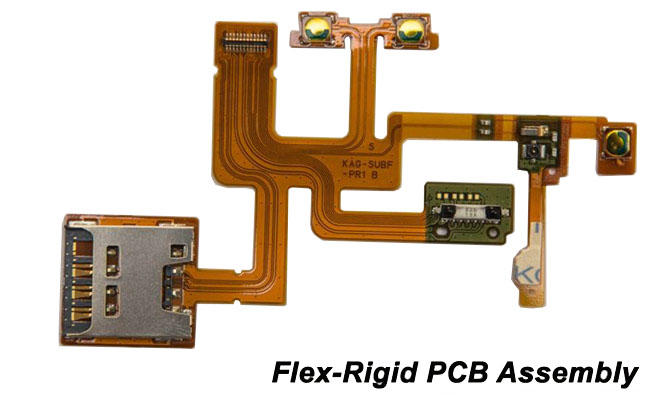

Rigid-Flex PCB:

Rigid-Flex printed circuit boards are designed to provide solutions, and act as replacements for rigid PCBs. As the

name suggests, these circuit boards are a hybrid of flex and rigid circuits. The advantage of this type is that they

exhibit the benefits of both rigid as well as flexible circuit boards.Most rigid-flex circuit boards consist of multiple

layers of flexible circuit substrates attached to rigid boards externally and/or internally. The flexible substrates

are designed to be in a constant state of flex, and are usually formed in a flexed curve during manufacturing or

installation. This is dependent upon the design of the application

Features of Rigid-Flex PCB:

- The designing of this board is a little bit difficult compared to a rigid circuit board because this module is designed

according to a three-dimensional environment that also provides high spatial efficiency.

- The main benefit of this board is that it provides highly flexible, decreases flex thickness and less expensive circuit

board.

- As on the tradition printed circuit board we can assemble large no of components on any side of a rigid circuit

board.

- Since the incorporation that exits among rigid and flex circuitry, a rigid-flex assembly does not use connectors

among the units. In its place, the flex circuitry electrically joins the scheme together.

- The absence of connectors provides some benefits that are mentioned here.

- It increases the capability of circuitry to send a signal with less distortion.

- Houses precise impedance value.

- It reduces joining issues like cold connections.

- It also decreases the weight of the board.

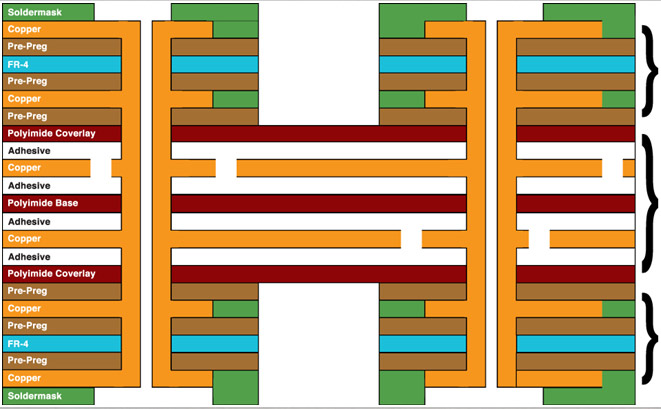

- Each rigid-flex printed circuit board divided into different parts that have different categories of layers and quantity.

- The number of layers can be larger than the flexible portion and construction substance can be

FR4 (Flame Retardant) or polyimide.

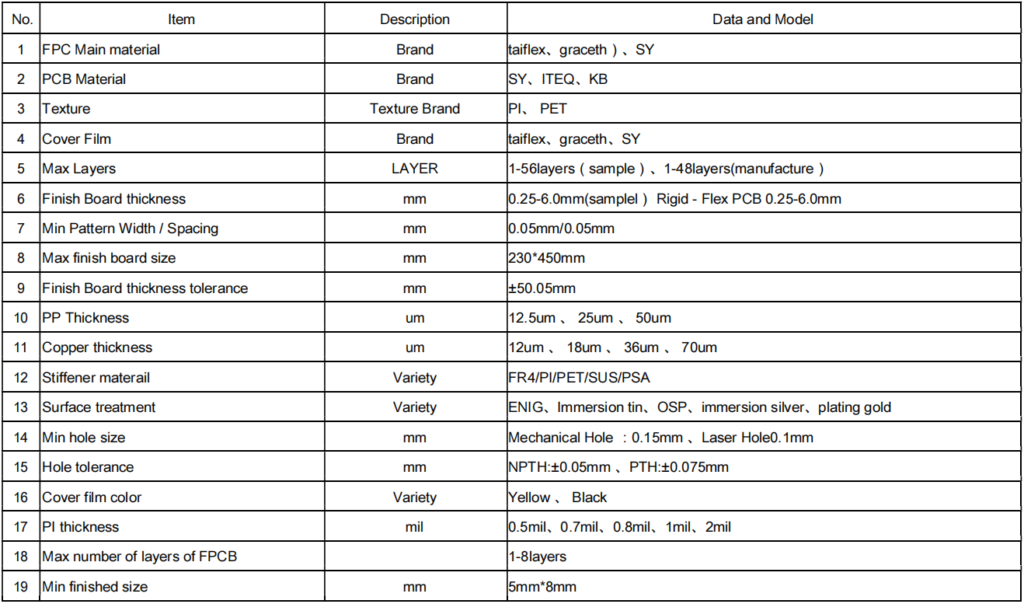

Rigid-Flex PCB Techincs Capacity: